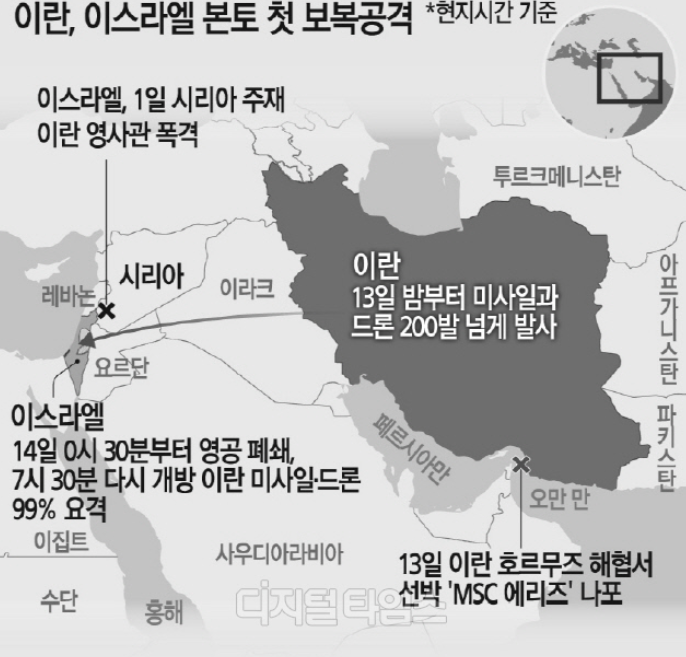

이란이 쏜 드론·미사일 200발, 세계 안보·경제 강타

이란이 시리아 내 자국 영사관 공격에 대한 보복으로 이스라엘에 대규모 심야 공습을 단행했다. 이스라엘은 아이언돔 등 자국 방공체계를 활용, 심각한 피해없이 방어한 뒤 재보복에 대한 검토에 들어갔다. 이란의 이스라엘 본토 공격은 1948년 이스라엘 건국 이래 사실상 처음이다. 이란은 최근 중동 동맹과 서방 국가들에 이번 보복이 전면적인 역내 전쟁으로 확대되는 것을 막기 위해 ‘영점 조정된'(calibrated) 방식으로 …